What is Spalling in Concrete?

Essential Tips to Protect and Repair Your concrete

Introduction:

Concrete is an indispensable material in the world of construction, appreciated for its strength and durability. But like all materials, it can experience wear and tear over time, leading to various issues.

One such problem, which can cause significant damage if not addressed promptly, is spalling. But what exactly is spalling in concrete?

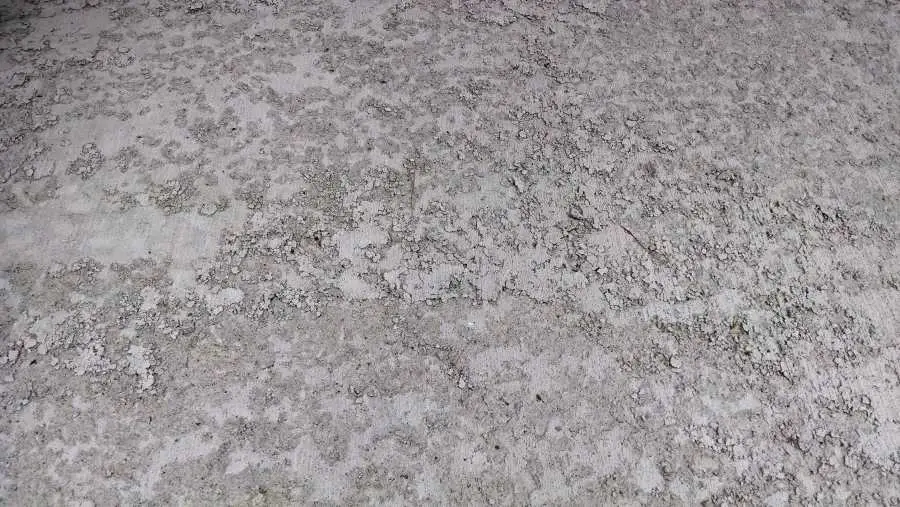

Spalling concrete refers to the process where the concrete surface layer begins to chip, flake, or break off, often creating pits or larger areas of material loss. It often looks like the concrete is peeling away in layers, which can not only be unsightly but also dangerous, affecting the integrity of the structure.

This blog post aims to delve deeper into this common concrete problem, explaining what causes it, how it can be prevented, and how it can be repaired.

what causes concrete spalling

There are various causes behind the occurrence of concrete spalling, often related to environmental factors, poor construction practices, or the natural aging process of the material. The most common causes include:

- Freeze-Thaw Cycles: In colder regions (northern states), water can seep into the concrete. When the temperature drops, the water freezes and expands, this internal pressure causes the concrete to crack and eventually spall.

- Corrosion of Reinforcing Steel: If the rebar, or embedded metals, inside the concrete rusts, it can expand up to four times its original volume, putting pressure on the surrounding concrete and causing it to spall. Having an adequate cover of concrete around any steel will help prevent this.

- Poor Construction Practices: Concrete spalling can also be the result of poor construction practices. If the concrete mix is not correct it could lead to weak concrete, or if the concrete is not properly placed, finished, and cured, it can lead to spalling and pit marks.

- Chemical Exposure: Certain chemicals can deteriorate concrete over time. For example, deicing salts used on roads in winter can contribute to spalling, leaving pit marks. This is common on a concrete driveway where the driveway meets the roadway.

how do you prevent spalling concrete

Preventing concrete spalling can save you a lot of money for concrete repairs. Here are some of the best ways to prevent this common issue:

Proper Mixing and Placement: Ensuring a proper mix of concrete is paramount. An ideal mix would contain the right proportions of cement, aggregates, and water. Overly wet concrete can increase the chances of spalling, as can concrete that is too dry. Equally important is the correct placement and compaction of the concrete to eliminate air pockets which can lead to spalling.

Adequate Curing: Correctly curing the concrete is another essential step. Curing allows the concrete to reach its maximum strength and durability, reducing its vulnerability to spalling. This process should take at least seven days but may take longer depending on the specific project and environmental conditions.

Use of Air-Entrained Concrete: In colder climates with freezing and thawing cycles, using air-entrained concrete can help prevent spalling. This type of concrete placement contains tiny air bubbles that provide room for water to expand when it freezes, thus reducing the likelihood of cracking and spalling.

Appropriate Concrete Cover Over Reinforcing Steel: To prevent the corrosion of steel bars, an adequate layer of concrete cover should surround the rebar. This concrete cover provides a barrier to the elements, helping prevent the steel bars from rusting and causing the surrounding concrete to spall.

Seal the Surface: Applying a protective coating or concrete sealer can provide an extra layer of protection against spalling. The sealer can repel water, deicing chemicals, and other damaging substances, thereby preventing them from seeping into the concrete and improving its aesthetic appearance.

Regular Maintenance and Inspection: Finally, regular inspection of the concrete surface can help identify signs of spalling early on. Prompt repair of minor cracks and damages can prevent them from progressing into significant spalling.

By adopting these preventative measures, the longevity and structural integrity of concrete structures can be significantly enhanced, and the occurrence of concrete spalling can be effectively minimized.

how to repair and fix spalling concrete

If preventive measures were not enough, or if the concrete structure has aged significantly, spalling may occur. Here are five ways to repair a spalled concrete surface effectively:

- Concrete Resurfacing: One of the most common ways to repair spalled concrete is to resurface the affected area. This involves cleaning the area, removing loose concrete, applying a bonding agent, and then applying a new layer of concrete or a concrete resurfacing product. This method is often best for superficial spalling.

- Use of Concrete Patch Products: For small to medium-sized areas of spalling, concrete patch products can be used. These typically involve a pre-mixed compound that can be applied to the area, filling in the spalled sections and restoring the surface.

- Concrete Replacement: In more severe cases, where the structural integrity of the concrete is in question, the affected area might need to be removed and replaced entirely. This involves breaking away the damaged concrete, installing new reinforcement if necessary, and pouring new concrete.

- Epoxy Treatments: Epoxy treatments can be particularly useful in instances where spalling has been caused by reinforcing steel corrosion. The corroded steel is treated and coated with a rust inhibitor, and the area is then filled with an epoxy filler.

- Application of Corrosion Inhibitors: For spalling caused by embedded reinforcing steel corrosion, the application of corrosion inhibitors can slow down the rusting process and prevent further spalling. These can be applied as a preventative measure when repairing spalled concrete to extend the lifespan of the repair.

Step-by-Step Guide to Fixing Spalled Concrete Driveway with Sakrete's Flo-Coat Concrete Resurfacer

Preparation: Begin by cleaning the area thoroughly. Use a high-pressure washer to remove dirt, grease, and any loose or broken concrete. Any cracks or holes larger than 1 inch should be filled with a suitable concrete repair material before resurfacing.

- Priming: Once the surface is clean and dry, apply a concrete bonding adhesive to the driveway. This will ensure a strong bond between the existing concrete and the new surface. Allow the adhesive to become tacky before applying the Flo-Coat.

- Mixing: Pour the Flo-Coat Concrete Resurfacer into a five-gallon bucket. Gradually add water according to the manufacturer's instructions, usually at a ratio of about 3.5 quarts of water for every 20 pounds of resurfacer. Mix with a paddle mixer until the consistency is uniform, lump-free, and pourable but not too thin.

- Application: Pour the mix onto the driveway and spread it evenly using a long-handled squeegee. For an even smoother finish, you can go over the surface with a concrete broom or trowel. Ensure that you apply the Flo-Coat at the recommended thickness (usually about 1/16th to 1/8th of an inch).

- Curing: Allow the resurfacer to cure for at least 24 hours before allowing foot traffic, and wait 72 hours before allowing vehicles. Protect the surface from the elements during this curing period.

- Sealing: After the surface has cured, it's a good idea to apply a concrete sealer to protect your newly resurfaced driveway from water damage and other potential causes of spalling.

By following these steps, you can repair spalling in your concrete driveway and restore it to a like-new condition.

how to fix smaller areas of spalling concrtete

Step-by-Step Guide to Fixing Spalled Concrete with Sakrete's Top N Bond Concrete Patcher

Preparation: Start by cleaning the spalled area thoroughly. Remove any loose concrete, dust, and debris. This can be done using a wire brush or a pressure washer. Make sure the surface is clean and free of sealers, curing compounds, and any other materials that could hinder adhesion.

- Wetting: Dampen the cleaned concrete area with water, but ensure there's no standing water. The surface should be saturated surface dry (SSD), which means the concrete is wet but there's no water pooling on the surface.

- Mixing: Pour the Top N Bond Concrete Patcher into a bucket, then slowly add water according to the manufacturer's instructions. Mix thoroughly until you have a smooth, lump-free consistency. The mixture should be firm enough to apply but wet enough to bond properly.

- Application: Apply the Top N Bond mixture to the spalled area using a trowel. Press firmly to ensure good contact with the existing concrete. Depending on the depth of the spalled area, you might need to apply multiple layers. Each layer should be no more than 1/2 inch thick. If a second layer is required, score the first layer with a trowel before it dries to ensure good bonding between layers.

- Finishing: Once the final layer is applied, smooth the surface with a trowel or brush. Aim to blend the repaired area with the surrounding concrete.

- Curing: Cover the repaired area with plastic for at least 24 hours to allow it to cure slowly. This helps prevent the patch from drying out too quickly, which can lead to shrinkage and cracking.

- Sealing: After the patched area has fully cured, consider applying a concrete sealer to protect against future damage.

By following these steps, you can effectively repair spalled concrete with Sakrete's Top N Bond Concrete Patching material.

How To Repair a Spalled Concrete Floor with an epoxy flake coating

I do a lot of epoxy flake coatings on garage floors that have concrete spalling in various degrees of damage.

To fix the spalled areas, I use a product called Quik Fix. It's a 2 part, fast-setting, hybrid urethane concrete repair patching material.

To see how we use Quik Fix to repair spalled concrete, watch this video of us applying an epoxy flake coating to a very badly damaged garage floor.

What's the difference between concrete spalling and scaling?

Spalling and scaling are two different types of damage that can occur in concrete, each with its own causes and characteristics.

Concrete Spalling: As discussed earlier, spalling occurs when the concrete surface begins to chip, flake off, or break away, often resulting in deeper pits or larger areas of material loss. Spalling often appears as if the concrete is peeling away in layers. This damage can be due to various causes, including freeze-thaw cycles, salt-laden air, corrosion of reinforcing steel, improper concrete mix, fire exposure, de-icing salts, or exposure to harsh chemicals.

Concrete Scaling: Scaling, on the other hand, is a type of surface damage that occurs when the top layer of the concrete starts to peel off or flake away. This usually affects only the surface layer of the concrete, without causing deeper pits or structural damage. Scaling usually results in an exposed aggregate appearance on the surface. The primary cause of scaling is often freeze-thaw cycles, especially in concrete that was not properly air-entrained, cured, or sealed. The use of deicing salts can also exacerbate scaling.

So in summary, while both spalling and scaling involve flaking or peeling of the concrete, they differ in terms of the depth of the damage (spalling usually penetrates deeper into the concrete), the appearance of the damaged area, and the causes.

What is concrete delamination vs spalling?

Concrete delamination and spalling are both types of deterioration that can occur in concrete structures, but they have different characteristics and causes.

Concrete Delamination: Delamination refers to a situation where the top layer of concrete separates from the underlying layer. This happens when air or water gets trapped between layers of concrete during the pouring and setting process, creating a weak bond between them.

Over time, these layers can separate or "delaminate." Delamination often manifests as a hollow sound when the surface of the concrete is tapped, and it may not be visually apparent until the delaminated layer starts to break away.

Concrete Spalling: As previously explained, spalling occurs when chunks of concrete start to break off from the surface, often resulting in deeper pits or larger areas of damage. This damage is often visible to the naked eye and can occur due to a variety of reasons including freeze-thaw cycles, improper curing or compaction, chemical exposure, or corrosion of reinforcing steel.

While both delamination and spalling can affect the integrity and appearance of concrete, they are different issues that require different methods of detection and repair.

Delamination is typically a subsurface issue that may not be visible until the surface layer starts to deteriorate or spall, while spalling is usually immediately apparent due to the visible damage to the surface of the concrete.

Can Alkali-Silica Reaction lead to spalled concrete?

The alkali-silica reaction (ASR) is a chemical reaction that occurs in concrete between the alkaline cement paste and reactive silica found in certain types of aggregate. Here's a detailed explanation and how it can lead to spalling:

Alkali-Silica Reaction (ASR): Over time, the alkaline (high pH) cement paste can react with silica present in the aggregates if they are of a reactive type. This reaction forms a gel-like substance. When this gel absorbs water, it can expand and create pressure inside the concrete.

The pressure from the expanding gel can lead to cracking and, eventually, the spalling of the concrete surface. The cracking often appears as a pattern of random cracks spread across the surface, sometimes referred to as 'map-cracking'. Besides, the gel can often be seen oozing out of the cracks and staining the concrete surface.

Prevention of ASR: To prevent ASR, non-reactive aggregates should be used when mixing concrete. In cases where reactive aggregates are used, a pozzolanic material such as fly ash, metakaolin, or silica fume can be added to the mix design. These materials can react with the alkali in the cement paste, reducing its availability to react with the silica in the aggregate. Another preventive measure is to limit the amount of alkali in the cement.

ASR and Spalling: In terms of causing spalling, the process is indirect. The pressure build-up from the ASR can lead to internal cracking, compromising the concrete quality and its structural integrity. Over time, these internal cracks can reach the surface, causing pieces of the concrete to break away or spall.

It's important to note that ASR damage is a slow process and can take years or even decades to become visible. Once ASR has started, it's very difficult to stop or reverse, so prevention is the most effective strategy.

In Conclusion:

Spalling in concrete is a common issue that can significantly impact the longevity and structural integrity of concrete structures. It's essential to understand what spalling is, the various factors causing it—ranging from freeze-thaw cycles, incorrect concrete mix and placement, to chemical damage and alkali-silica reactions—and the steps needed to prevent it.

We've also discussed how to repair spalled concrete using various methods such as resurfacing, patching, complete replacement, epoxy treatments, and corrosion inhibitors. Specific products, like Sakrete's Flo-Coat Concrete Resurfacer and Top N Bond Concrete Patcher, have been outlined to help guide a successful repair process.

In all cases, maintenance and regular inspections play a vital role in the early detection and prevention of concrete spalling. For severe cases or when in doubt, it's always recommended to seek professional advice to ensure the structural safety and durability of your concrete structures.

By adopting proactive measures and suitable repair methods, you can significantly enhance the lifespan and quality of your concrete, saving you time and money in the long run.

Some of my most popular pages: