What Is Shotcrete concrete?

Shotcrete is a type of concrete that is sprayed onto a surface using a high-pressure air compressor.

It is often used for repair and construction projects in hard-to-reach or complex areas where conventional pouring methods are not feasible.

The shotcrete mixture is made up of dry concrete ingredients that are mixed with water and then pumped through a hose to the nozzle, where compressed air is added to propel the mixture onto the surface.

The fast-setting mixture then solidifies and hardens, forming a strong and durable layer of concrete.

Shotcrete being applied to a vertical surface

Shotcrete being applied to a vertical surfacewhat is the purpose of using shotcrete?

Shotcrete is used for a variety of purposes, including:

- Structural Repair: Shotcrete is often used to repair cracks, leaks, and other structural damage in concrete structures such as bridges, tunnels, and buildings.

- Construction: Shotcrete is often used to build retaining walls, bridges, tunnels, and underground structures.

- Fireproofing: Shotcrete can be used to provide fireproofing to concrete structures, as it has excellent insulation properties.

- Mining: Shotcrete is widely used in the mining industry for support and lining of underground mines.

- Landscaping: Shotcrete can be used to create rock formations, water features, and other architectural elements in landscaping projects.

- Slope stabilizationisation: Shotcrete is used to stabilize slopes and embankments, particularly in areas prone to landslides.

In general, the main advantage of shotcrete is its versatility, speed of application, and ability to be applied in difficult or hard-to-reach locations, making it an ideal solution for many construction and repair projects.

is shotcrete stronger than concrete?

The strength of shotcrete concrete depends on several factors, including the mix design, the application method, and the curing process.

In general, shotcrete can have similar strength to conventional concrete if it is properly designed, mixed, and cured.

However, in some cases, shotcrete can be stronger than conventional concrete due to the high-pressure application and the ability to achieve a more dense and compact layer of concrete. It's common to find compressive strengths of shotcrete in the range of 6,000 to 7,500 psi.

This is particularly true for shotcrete used in mining, where high strength is essential to support the weight of the rock overhead.

It is important to note that the strength of shotcrete concrete also depends on the type of aggregate and the type of binder (cement, fly ash, etc.) used in the mix.

It is also essential to follow proper curing procedures to ensure the maximum strength and durability of the shotcrete layer.

What is the advantage of using shotcrete vs concrete?

There are several advantages of using shotcrete compared to conventional concrete:

- Speed: Shotcrete can be applied quickly, reducing the time required for construction or repair projects.

- Versatility: Shotcrete can be applied to a variety of surfaces, including vertical, overhead, and irregular surfaces, making it ideal for difficult or hard-to-reach areas.

- Ease of application: Shotcrete can be applied with a relatively small crew and minimal equipment, making it cost-effective for many projects.

- Customization: Shotcrete can be customized to meet specific project requirements, such as fire resistance or rapid setting time.

- Reduced waste: Shotcrete generates minimal waste compared to conventional concrete, as it is mixed and applied on-site as needed.

- Increased strength: Shotcrete can provide increased strength and durability compared to conventional concrete, particularly when applied at high pressure.

- Reduced settling: Shotcrete has a reduced tendency to settle or crack compared to conventional concrete, making it ideal for use in areas prone to settling, such as slopes and embankments.

It is important to note that the choice between shotcrete and conventional concrete will depend on the specific requirements of each project, such as the location, the surface to be covered, and the desired strength and finish.

how thick can shotcrete be applied?

The thickness of shotcrete that can be applied depends on several factors, including the type of shotcrete mix, the substrate, and the equipment being used.

Typically, shotcrete can be applied in layers ranging from 50 mm to 200 mm (2 inches to 8 inches) in a single application, although thicker layers can be achieved by applying multiple layers and allowing each layer to cure before applying the next.

The maximum thickness of a single shotcrete layer will depend on the properties of the shotcrete mix, the underlying substrate, and the air pressure and volume being used.

It is important to follow the manufacturer's recommendations and industry guidelines to ensure the shotcrete layer is properly compacted and cures to the desired strength.

In general, the use of high-quality materials, proper mix design, and proper application techniques will result in a shotcrete layer with increased durability and strength.

Does shotcrete need to be sealed?

Whether shotcrete needs to be sealed depends on the specific application and the desired outcome. In some cases, sealing shotcrete may be necessary to improve its durability and longevity.

Here are some reasons why shotcrete may need to be sealed:

- Protection against moisture: Sealing shotcrete can prevent moisture from penetrating the surface, which can cause cracking, spalling, and other forms of damage.

- Protection against chemicals: Sealing shotcrete can prevent chemicals, such as acids, salts, and solvents, from penetrating the surface and causing damage.

- Aesthetic reasons: Sealing shotcrete can enhance the color and texture of the surface, making it more attractive and uniform.

It is important to note that sealing shotcrete is not always necessary and may not be appropriate for all applications. Factors such as the intended use, the exposure conditions, and the desired appearance will determine whether sealing is required.

When in doubt, it is always best to consult with a professional to determine the best course of action for sealing shotcrete.

what is the difference between shotcrete and gunite?

Shotcrete and gunite are two methods of applying concrete using a high-pressure air compressor, but there are some key differences between the two.

- Mix Design: The main difference between shotcrete and gunite is the mix design. Shotcrete uses a wet mix of concrete that is poured into the nozzle and mixed with compressed air, while gunite uses a dry mix of concrete that is mixed with water just before it is applied.

- Application Method: Shotcrete is typically applied using a nozzle that is attached to a flexible hose, while gunite is typically applied using a rigid pipe.

- Compression: Shotcrete is typically applied at a higher air pressure and velocity than gunite, resulting in a denser and more compact layer of concrete.

- Setting Time: The setting time of shotcrete is generally faster than gunite due to the wet mix design, which allows the concrete to set more quickly.

In general, shotcrete is favored for applications that require a fast-setting and high-strength concrete, while gunite is favored for applications that require a dry mix and a more controlled application process. The choice between shotcrete and gunite will depend on the specific requirements of each project and the desired outcome.

what is a shotcrete pool?

Image courtesy of Shotcrete Custom Pools

Image courtesy of Shotcrete Custom PoolsA shotcrete pool is a type of swimming pool that is constructed using shotcrete, a type of concrete that is sprayed onto a surface using high-pressure air.

The shotcrete mixture is made of Portland cement, aggregate, and water, and is applied to a surface to form the walls, floor, and other elements of a swimming pool.

Shotcrete pools are known for their durability, strength, and versatility, making them a popular choice for both residential and commercial swimming pools.

They can be designed to fit a variety of shapes, sizes, and styles, and can be customized with features such as waterfalls, slides, and steps.

One of the main benefits of shotcrete pools is the speed and ease of construction. Shotcrete can be applied quickly and efficiently, reducing the time and cost of construction compared to other types of pools.

Additionally, shotcrete pools are known for their ability to withstand harsh weather conditions and heavy usage, making them a durable and long-lasting option for swimming pools.

It is important to note that shotcrete pools require proper maintenance and upkeep to ensure their longevity and performance.

This includes regular cleaning, balancing the water chemistry, and sealing the surface to prevent cracking and other forms of damage.

The Benefits of Decorative Shotcrete

The shotcrete process is popular in many industries: pools, theme parks, underground tunneling, skate parks and retaining walls. Products made from using shotcrete are all around us but rarely noticed.

There many examples of decorative shotcrete products. Some you may have already seen, but not realized it was shotcrete.

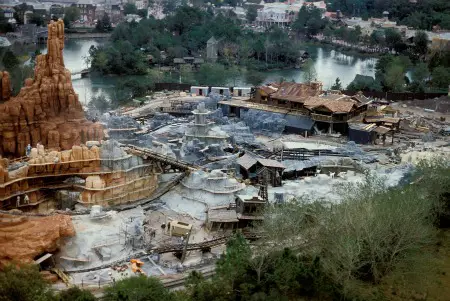

Walt Disney Worlds Splash Mountain and Big Thunder Mountain Railroad have structural and decorative concrete applied through the shotcrete process.

Shotcrete was used to form the rocks at Big Thunder Mountain in Walt Dinsey World

One sided forming with unlimited shape potential makes shotcrete a perfect material for pools. Residential home construction, renovations and commercial projects can all take advantage of the shotcrete process for retaining walls, faux rock finishes, decking or high-rise facades.

For other interesting facts about concrete click on

Return from What is Shotcrete to History of Concrete

Return from What is Shotcrete to Everything About Concrete Home Page