How Long Does it Take Concrete to Cure?

Concrete sets in approximately 24 to 48 hours, allowing for light foot traffic or vehicle use.

However, the curing process is ongoing and gradual, with the concrete reaching its full strength potential after 28 days.

I'm using a curing compound to properly cure the concrete

I'm using a curing compound to properly cure the concreteThese are the key timeframes to keep in mind while waiting for concrete to dry:

- Within 24 to 48 hours: The initial set has taken place, allowing for form removal and light foot traffic.

- After 7 days: The concrete has undergone partial curing, and it is safe for vehicles and equipment to be used on the surface.

- At 28 days: The concrete should have reached full strength and be considered fully cured.

This concrete floor will need to be cured after finishing is done.

This concrete floor will need to be cured after finishing is done.For concrete to achieve its desired strength and durability, it is essential that it undergoes proper curing for an adequate length of time.

Curing is the process of ensuring that placed concrete has sufficient moisture for hydration, a process in which the cement chemically reacts with water molecules, to make it as strong and durable as expected.

Insufficient curing results in weak concrete that is susceptible to cracking, abrasion, and other negative effects.

Simply put, the longer your concrete is continuously hydrated, the longer it will cure and the better the result.

So how long does it take for concrete to cure? This blog post answers that question while addressing other vital factors contributing to concrete curing.

But before then, let's take a look at the difference between concrete curing and concrete drying.

Concrete curing vs concrete drying

It is common for people, especially customers, to use the term ‘ curing’ and ‘drying’ interchangeably when describing concrete. However, these two words mean completely different things.

Concrete drying is a dehydration process whereby moisture is removed from within concrete through its surface. In contrast, concrete curing is a hydration process whereby moisture is added or retained inside the concrete.

It is, in fact, possible to have perfectly dried concrete that is yet improperly cured; can you believe that? While concrete can become dry enough for foot traffic within 24-48 hours, that is not enough time for it to be adequately cured.

The process of curing is crucial in determining the strength of the final concrete product. To ensure proper development, it is essential to maintain the concrete within a suitable range of relative humidity and temperature during the curing period.

If this doesn't happen or happens insufficiently, the concrete dries prematurely and turns out not as strong and durable as it should be in the long term.

How to Achieve Proper Curing

When concrete is placed, it is important to control its moisture loss. This involves properly maintaining the right temperature and moisture level for a set amount of time. Doing this contributes to the setting, hardening, strength, and durability of the concrete in the long term.

Here are three different methods of curing concrete:

USING WATER TO CURE CONCRETE

This is the most common and considered the best method of curing because it is great at promoting hydration, absorbing heat, and preventing shrinkage.

Spraying water to cure concrete

Spraying water to cure concrete- Flooding: This method involves regularly flooding the concrete surface with water to maintain a constant level of moisture. The concrete is usually covered with plastic sheets to prevent evaporation. This method is simple, cost-effective, and suitable for small-scale projects.

- Spraying: This method involves spraying water onto the concrete surface using a hose or a spray system. This method is more efficient than flooding, as it ensures even distribution of moisture over the concrete surface. It is also less labor-intensive and can be used for larger projects.

- Immersion: This method involves completely immersing the concrete in water. This method is typically used for precast concrete products, such as pipes, that need to be cured underwater. Immersion provides the concrete with a constant supply of moisture, which is necessary for proper hydration and strength development. However, it requires specialized equipment and facilities, and is not practical for most construction projects.

- Saturated wet coverings: These are materials constantly kept moist and are usually placed on the surface of the concrete after it has hardened sufficiently to prevent damage. A couple examples are burlap and curing paper.

Note that the water used for curing, in the above methods, should not be more than about 5°C (10°F) colder than the concrete surface, as cracking due to thermal shock may occur when warm concrete is sprayed with cold water.

Spraying on a curing compound

Spraying on a curing compoundWATER RETENTION METHOD BY CURING COMPOUNDS (membrane method)

Great for intermediate curing— when placed concrete hasn't reached its final set—, this method helps to prevent or reduce evaporation of moisture from concrete and can be done in three major ways including;

- Left in place forms: These are solid barriers that provide satisfactory protection against moisture loss for formed concrete surfaces and are usually left in place as long as the construction schedule allows. Depending on what they are made of, these forms are almost always kept wet, especially during hot, dry weather.

- Covering concrete with waterproof paper or plastic sheets: These are materials usually applied on well-moistened floors with a surface hard enough to prevent damage.

- Applying membrane-forming curing compounds: These compounds (sealers) are best applied immediately after the final finishing and aim to delay or reduce moisture evaporation from the concrete.

TEMPERATURE CONTROL METHOD:

With higher temperatures, concrete’s hydration process speeds up, leading to faster strength development. Different means of temperature control methods include;

- Ordinary temperature steam curing: In this process, concrete - usually prefabricated - is exposed to steam in a chamber, resulting in increased hydration and strength within 3 days.

- High temperature and pressure steam curing: In this method, steam is applied to the concrete at a very high temperature and pressure. This method helps the concrete develop strength within a day or less while helping it remain durable over a long period.

- Heating coils: These serve as embedded elements, usually placed near the concrete surface. They help protect the concrete from freezing in cold weather.

- Electrical heated forms or pads: In this method, the concrete is surrounded with large electric pads or molds that heat the concrete as they are heated. However, this method is not economical and is rarely used.

- Concrete blankets: Concrete insulation blankets are used to cover and insulate concrete surfaces subjected to freezing temperatures during the curing period. The concrete should be hard enough to prevent surface damage when being covered with concrete blankets.

When choosing the right curing method for your concrete, it is important to consider your type of construction (floor or walls), the location (indoors or outdoors), and the weather conditions.

Concrete Curing Timeline

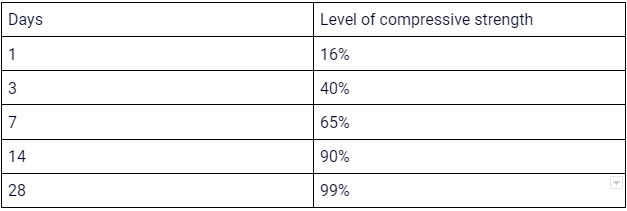

When concrete is fully cured, it has reached its maximum capacity or full compressive strength. This, of course, happens gradually over the course of days.

- At 24-48 hours after setting, concrete cures enough for some foot traffic

- At 7 days, concrete cures enough for some vehicular traffic

- At 28+ days, concrete cures to its full capacity

The following table illustrates the progression of concrete curing over various time intervals.

Other factors that may influence the duration of the curing period include:

- Mix Design: The composition of the concrete mix, including the type and amount of cement, aggregate, water, and admixtures, can affect the curing time.

- Ambient Temperature: High temperatures can speed up the curing process, while low temperatures can slow it down.

- Humidity: High humidity can assist in curing, while low humidity can reduce the curing rate.

- Air Flow: Good air circulation helps to regulate temperature and humidity, promoting a faster and more consistent curing process.

- Surface Area: The larger the surface area of the concrete, the more quickly it will lose moisture, affecting the curing time.

- Thickness: Thicker concrete slabs will require more time to cure than thinner ones.

- Type of Cement: Different types of cement have different chemical compositions and curing times.

- Admixtures: Certain chemical admixtures can accelerate or slow down the curing process.

- Method of Curing: Different methods of curing, such as water curing, membrane curing, or steam curing, can have a significant impact on the curing time.

- Exposure Conditions: Exposure to sun, wind, rain, or other environmental conditions can affect the curing process and may require additional protection.

final thoughts

Proper curing of concrete is important because it has a direct impact on the concrete's strength, durability, and overall quality.

Concrete curing is a critical step in the concrete construction process, as it allows the concrete to reach its maximum strength, which is necessary for it to perform as intended in its final application.

Failing to cure concrete properly can result in poor concrete quality, increased porosity, reduced strength, and increased risk of cracking, which can compromise the integrity of the structure and shorten its service life.

Therefore, it is essential to follow proper curing procedures and guidelines to ensure that the concrete reaches its maximum potential and provides the desired performance and longevity.