what can i use to strip concrete sealer?

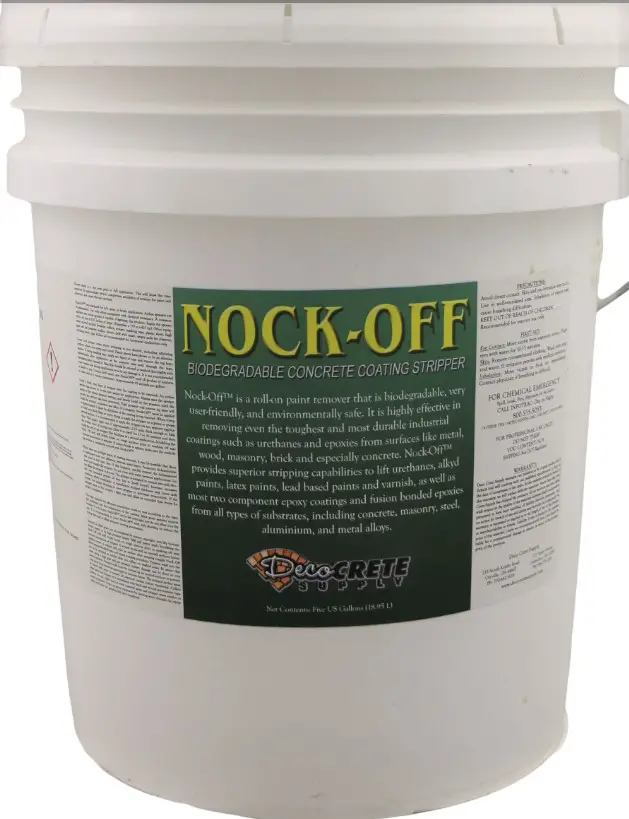

Nock-Off is a roll-on sealer, coating, and paint stripper-remover that is biodegradable, environmentally safe, and user-friendly.

This product is highly effective in stripping and removing tough industrial coatings such as urethanes and epoxies from various surfaces, including concrete, metal, wood, masonry, and brick.

Nock-Off provides superior stripping capabilities, making it capable of lifting acrylic concrete sealers, alkyd paints, latex paints, lead-based paints, varnish, as well as most two-component epoxy coatings and fusion bonded epoxies from all types of substrates. This includes concrete surfaces and masonry.

One of the notable features of Nock-Off is its biodegradability and eco-friendliness, making it an ideal choice for those who prioritize environmental safety.

Additionally, its user-friendly nature makes it easy to apply, further increasing its appeal to a wider audience.

Overall, Nock-Off is a highly effective and versatile product capable of removing various coatings from different surfaces.

Its biodegradability, user-friendliness, and effectiveness make it an ideal choice for those seeking a safe and efficient concrete sealer, coating and paint remover / stripper.

key features of nock-off

One of the key features of this product is its high effectiveness on many coatings, including industrial-grade products. This ensures that it can efficiently remove tough coatings without compromising on quality.

Another notable feature is its superior stripping capabilities, which can help save money compared to high-cost mechanical stripping methods. This makes it an economical option for those who are looking for a cost-effective solution to remove coatings.

Furthermore, this product is non-flammable and fully biodegradable, ensuring that it is safe for use and does not pose a fire hazard. It also contains no carcinogens and does not deplete the ozone, making it an environmentally friendly option.

Lastly, this product contains 0 g/L VOC content, which makes it legal for sale in all regions of the US and Canada. This makes it an ideal choice for those who are looking for a compliant and safe product that meets all legal requirements.

designed to strip sealers and coatings such as:

Nock-Off was designed to remove the following sealers & coatings:

- Solvent and Water based acrylic concrete sealers

- Water based Urethanes

- Alkyd paints

- Latex & Lead based paints

- Single and two-component epoxies

- Varnish

Nock-off surface prep and application instructions:

Here are the step-by-step instructions for surface prep and application of Nock-Off:

STEP 1. Always apply Nock-Off to a test area before full application to determine the approximate time required for project completion, product suitability for paint and substrate, and the most effective method of application.

STEP 2. Nock-Off was designed for roll, spray, or brush application, and airless sprayers are recommended. Use only airless equipment with chemical resistance. A medium-sized airless sprayer with a tip size of 0.02 inches or larger is capable of spraying this product.

STEP 3. Equip yourself with brushes, rollers, scrapers, masking tape, plastic sheeting, a high gpm and psi pressure washer, an electric drill with mixer, empty pails for clean-up, running water, and rags. For horizontal application, use rollers.

STEP 4. Cover and protect areas where stripping is not desired, including adjoining surfaces where over-spray may travel.

- Plastic sheets are effective barriers.

- If using masking tape, apply two layers and remove the top layer immediately after application, as the remover may soak through the tape, damaging the paint beneath it.

- Cover or wash thoroughly any plant life before and during application to avoid damage.

STEP 5. It's not recommended to shake Nock-Off to mix it. Use a drill mixer to mix until all product is uniform in color and of a creamy consistency.

STEP 6. Apply a thick, even layer of stripper, at a rate of 50 - 100 sq. ft. per gallon, onto the coating to be removed. An airless sprayer is the best means for application.

Start the sprayer pump at the lowest pressure setting, and slowly build up the pressure until the proper fan pattern has been generated.

Nock-Off must be applied at approximately two times the thickness of the coating being removed. For very thick films or when applying the stripper on a glossy or greasy vertical surface, apply the stripper via two separate applications.

- First, apply a light coat of approximately 12-15 mils, thick enough to hide the surface color of the coating and allow it to dwell for 15-30 minutes

- Then build the rest of the stripper film thickness in a second application. Scrubbing the Nock-Off with a stiff bristle brush on rough surfaces prior to washing off may increase penetration of stripper. If using a brush to agitate, make sure the underlying surface is completely covered with Nock-Off.

STEP 7. When there are multiple layers of existing SEALERS, it may be possible that there is inadequate inter-coat adhesion between some layers.

Premature delamination may occur at this interface. If this happens, quickly remove the delaminated layers and reapply the stripper.

- Do not rinse with water between applications.

- Do not allow the stripper to dry out.

The stripper is designed to remain wet and effective over extended periods of time (up to 24-48 hours)

- however, excessive sunshine, windy conditions, or insufficient stripper thickness may cause early drying.

- Use plastic sheeting to cover the stripper to minimize evaporation.

- If the stripper starts to dry, reapply a light coat and allow an extended time frame for project completion.

STEP 8. The time required for adequate penetration tends to vary according to the type, thickness, and temperature of the coating.

Most paint systems require between 2 to 36 hours. Nock-Off can be left overnight, but do not allow it to dry out.

It is recommended to cover Nock-Off with 3 or 4 mil poly sheeting to reduce the drying time and to allow adequate coating penetration.

STEP 9. Removal of lifted SEALER can be completed by scraper, squeegee, wet/dry vacuum suction system, or by high-pressure power wash.

Scrubbing the Nock-Off with a stiff bristle brush on rough surfaces prior to washing off may increase the penetration of the stripper.

A scraper works well on smooth surfaces before applying water. If residue still exists on the surface after scraping, reapply Nock-Off, allow reasonable dwell time, and repeat the scraping procedure.

Pressure wash into the area to be stripped so that the residue does not collect on washed areas. Be aware that when using a high gpm and psi pressure washer, damage can be done to concrete surfaces. Be careful getting the tip to close to the surface.

Pressure wash from the bottom up on vertical surfaces to prevent rinse water from deactivating stripper in sections below.

STEP 10. The stripped surface must be rinsed with water to remove all chemical residue before repainting. Collect lifted paint and dispose of it in accordance with local and federal government regulations. Do not collect and/or store removed paint and stripper waste residue in metal containers.

STEP 11. Clean up spray equipment by running water through the equipment soon after the spraying has been completed.

Following these steps will ensure proper application of Nock-Off and help achieve the desired results in removing concrete sealers from various surfaces.

Always use personal protective equipment during the application process, including gloves, eye protection, and respiratory protection. Proper ventilation should also be provided when using Nock-Off indoors.

limitations and precautions

- Nock-Off - will not freeze, but it is recommended to store it in an area between 65°F and 85°F.

- Nock-Off - will not strip all coatings, so it is important to test prior to the beginning of application to ensure product suitability.

- The coverage rates of Nock-Off depend upon many conditions, including application method, surface porosity, and applicator.

- Nock-Off - was designed for use on both interior and exterior surfaces.

- Nock-Off - should never be thinned or diluted with any kind of chemical or liquid.

Shelf life is up to one year from the manufacturer's date on the original, un-opened container, stored at room temperature.

It's packaged in 1 gallon, 5 gallon, and 55 gallon containers.

how to test if you have a slovent or water based sealer

To accurately remove a concrete sealer, it's important to first determine the type of sealer that was initially applied.

If you're unsure of the type of sealer used, you can follow these steps to determine whether the concrete was sealed with a water-based sealer or a solvent-based sealer:

- Pour a small amount of Xylene on an area that is still coated by the previous concrete sealer.

- Allow the Xylene to sit for 20 seconds, then remove any excess.

- Touch the area with your finger. If it feels tacky or sticky, then the surface was sealed with a solvent-based sealer.

- If the concrete is not tacky or sticky, then the concrete was sealed with a water-based sealer.

Knowing the type of sealer used is crucial in determining the appropriate method for removing the sealer.

If you already know the type of sealer that was applied, you can skip this step and proceed with the appropriate removal method.

what you should know about these questions:

1. Will vinegar remove concrete sealer?

- Vinegar is not an effective concrete sealer remover. While it may help to loosen some types of sealers, it is not strong enough to fully remove them.

2. Will Xylene remove concrete sealer?

- Xylene can be effective at removing certain types of concrete sealers, particularly solvent-based sealers. However, it's important to test a small area first and to take proper safety precautions when handling xylene.

3. Will TSP remove concrete sealers?

- Trisodium phosphate (TSP) isn't a concrete sealer remover. While it can be effective at removing certain types of coatings, it's not recommended for use on concrete surfaces due to the potential for etching and damage.

4. Will Acetone remove concrete sealer?

- Acetone is not generally recommended for removing concrete sealers. While it may work to loosen some types of sealers, it is not strong enough to fully remove them and may cause damage to the concrete surface.

5. Will Muriatic Acid remove concrete sealer?

- Muriatic acid is a strong and potentially dangerous chemical that can be used to remove concrete sealers. However, it should only be used as a last resort and with extreme caution, as it can cause damage to the concrete surface and can be hazardous to breath and touch. It is important to test a small area first and to take proper safety precautions when using muriatic acid.

faq's

Here are 10 more frequently asked questions people ask about stripping sealers, along with their respective answers:

1. How do I know if I need to strip the sealer on my concrete surface?

- Answer: If the sealer is faded, worn, or no longer providing adequate protection, then it may be necessary to strip it.

2. Can I strip the sealer myself or should I hire a professional?

- Answer: While it is possible to strip the sealer yourself, it can be a difficult and time-consuming task. Hiring a professional may be a better option if you are not experienced in stripping sealers.

3. What tools do I need to strip a sealer from concrete?

- Answer: The tools required for stripping a sealer may vary depending on the method chosen, but common tools include pressure washers, scrapers, and chemical strippers.

4. How do I choose the best sealer stripping method for my concrete surface?

- Answer: The best sealer stripping method will depend on the type of sealer used and the condition of the concrete surface. Using Nock-off is one of the best sealer stripping methods.

5. Can I use a pressure washer to strip sealers from my concrete surface?

- Answer: Yes, pressure washing is a common method for removing sealers from concrete surfaces. But, pressure washing alone may not completely strip off all the old sealer.

6. Is it safe to use chemical strippers for removing sealers?

- Answer: Chemical strippers can be safe when used properly, but it is important to follow all safety guidelines and wear appropriate protective equipment.

7. Will stripping the sealer damage my concrete surface?

- Answer: Stripping the sealer can potentially damage the concrete surface, but using the appropriate method and tools can minimize the risk.

8. Can I apply a new sealer immediately after stripping the old one?

- Answer: It's important to allow the concrete surface to dry completely before applying a new sealer, this usually takes between 24 - 48 hours depending on weather conditions.

9. How long does it take to strip a sealer from concrete?

- Answer: The time required to strip a sealer can vary depending on the method chosen, size of the project, and the condition of the concrete surface.

10. Do I need to seal my concrete surface after stripping the old sealer?

- Answer: Applying a new sealer after stripping the old one can help protect the concrete surface and extend its lifespan.

some other Types of chemical-strippers for concrete

Chemical removers and strippers come in three categories: bio-chemical, caustic, and solvent-based. You can purchase all three from a Lowe's, Home Depot, Sherwin-Williams or your local hardware store.

Here are 5 other types of chemical strippers for concrete sealers:

1. Soy-based strippers: These strippers are environmentally friendly and safe to use, making them a popular choice for removing sealers from concrete surfaces.

- Soy-Gel by Blue Bear is a popular soy-based stripper that is environmentally friendly and effective at removing concrete sealers.

2. Caustic strippers: Caustic strippers are strong alkaline solutions that work by breaking down the chemical bonds of the sealer. They can be effective but require careful handling due to their caustic nature.

- Klean-Strip Premium Stripper is a caustic stripper that is effective at removing a wide range of sealers from concrete surfaces.

3. Acidic strippers: Acidic strippers work by dissolving the sealer, making it easier to remove. However, they can be dangerous to handle and require special precautions.

- Krud Kutter Concrete & Driveway Pressure Washer Concentrate is an acidic stripper that works by dissolving concrete sealers for easy removal.

4. Biochemical strippers: These strippers use enzymes to break down the sealer and are often favored for their eco-friendliness and safety.

- Bean-e-doo Mastic Remover is a biochemical stripper that uses natural enzymes to break down and remove concrete sealers.

5. Solvent-based strippers: Solvent-based strippers use a chemical solvent to dissolve the sealer, making it easier to remove. They can be effective but require careful handling due to the flammable nature of the solvents used.

- Klean-Strip Xylol - Xylene is a solvent-based stripper that uses a powerful solvent blend to dissolve and remove sealers from concrete surfaces.

All these strippers have one thing in common, they need time to work and you have to keep them wet to stay active. Once they dry out they stop working.

Depending on the sealer type and thickness, multiple applications will probably be needed to remove all the sealer. This will take time, maybe hours, so plan accordingly.

Some strippers are in gel form, this helps them hold to the surface better and not dry out too fast, keeping them active longer.

Protect and cover anything you don't want to strip or kill (plants & grass) and always read and follow the manufactures specifications for best results.

Here's a breakdown of the different types of chemical strippers and how they work. This will you help choose the right stripper for your project.

in conclusion

In conclusion, stripping a concrete sealer can be a tedious task, but it is necessary for maintaining the quality and appearance of a concrete surface.

There are various methods for removing sealers, including pressure washing, scraping, and chemical stripping.

When choosing a chemical stripper, there are different types available, such as soy-based, caustic, acidic, biochemical, and solvent-based strippers.

Each type has its own benefits and potential drawbacks, so it is important to consider factors such as effectiveness, safety, and environmental impact when selecting a stripper.

By following proper surface preparation and application instructions, it is possible to successfully strip a sealer and apply a new one to protect and enhance the concrete surface.

Here's some related information about concrete sealers:

CONCRETE SEALER AND CONDENSATION PROBLEMS

CONCRETE SURFACE TEMPERATURE CAN CAUSE SEALER PROBLEMS

WHAT CAUSES SEALER BLISTERS AND BUBBLES?

SEALER SURFACE PREPARATION BEFORE SEALING

WHAT KIND OF SEALER APPLICATOR SHOULD I USE?