Can you paint over concrete sealer?

what you need to know before you let the paint flow!

Painting over concrete sealer is possible, but it requires proper preparation, the right tools, and the correct type of concrete paint to ensure a long-lasting and durable finish.

Whether you need to remove the sealer before painting largely depends on the condition of the sealer and the type of paint you choose.

It's crucial to follow the recommended steps, such as cleaning the surface, testing the sealer, sanding the surface, applying a primer, and using a compatible concrete paint formulated for painting over the concrete sealer.

By following these guidelines and choosing the right type of paint, you can transform your concrete surfaces into a fresh and attractive space.

How to determine what paint can be used on sealed concrete

(Check this first)

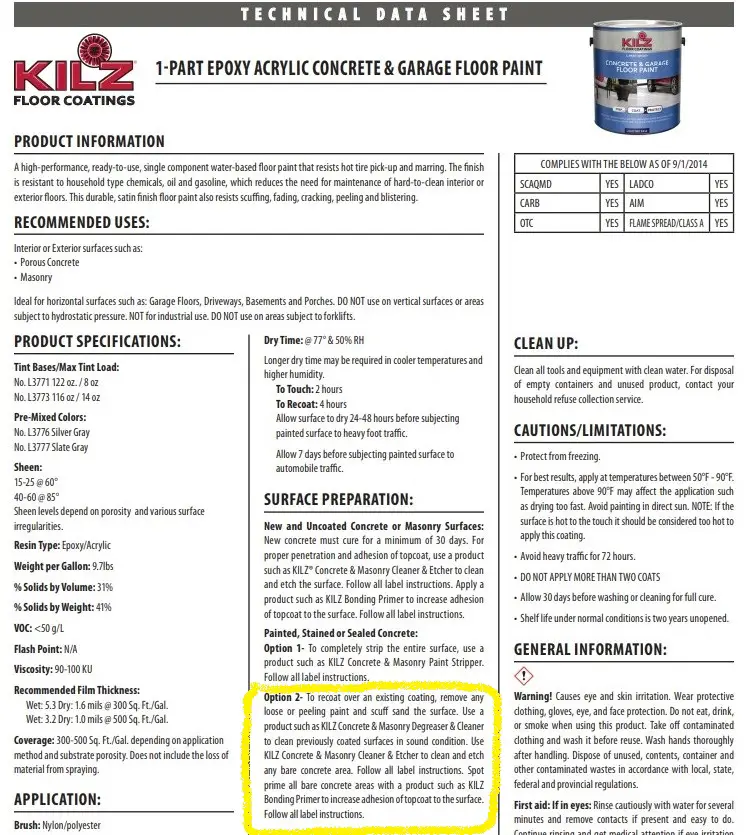

It's important to look at the technical data sheet (TDS) when choosing a concrete paint to apply over a sealed concrete surface to ensure compatibility, but also for proper surface preparation, and optimal application conditions.

Every manufacturer's concrete paint product has a TDS that has the following information:

- Compatibility: Not all concrete paints are compatible with every type of sealer. The technical data sheet provides crucial information on the paint's formulation, which can help you determine if it will adhere properly to the existing sealer.

- Surface preparation: The technical data sheet outlines the recommended surface preparation steps for optimal paint adhesion. These steps may vary depending on the type of sealer and paint, so it is essential to follow the manufacturer's guidelines for the best results.

- Application conditions: The data sheet will also provide information on the ideal temperature, humidity, and weather conditions for applying the paint. Applying the paint in unsuitable conditions can lead to poor adhesion, prolonged drying times, or other issues that may compromise the paint's performance.

- Priming requirements: Some concrete paints may require a specific primer or a particular type of primer for optimal adhesion when applied over a sealer. The technical data sheet will provide guidance on the appropriate primer to use, if necessary.

- Curing time: The data sheet will inform you of the recommended drying and curing times for the paint. This is important to ensure proper adhesion, especially when applied over a sealer. Applying additional coats or using the surface too soon can lead to poor performance and durability.

- Coverage and recoat information: The technical data sheet will also provide details on the paint's coverage rate, the number of coats needed, and the recoat window. This information is essential to ensure adequate coverage and a smooth, even finish when painting over a concrete sealer.

what paint can i use on sealed concrete?

When choosing a concrete paint to apply over a concrete sealer, it's essential to select a paint that is compatible with the existing sealer and specifically formulated for concrete surfaces.

Here are four types of concrete paint that can be used to paint over a concrete sealer:

- Kilz 1-Part Epoxy Acrylic Concrete & Garage Floor Paint: TDS says - To apply a new coat over an existing coating, first eliminate any loose or flaking paint and gently sand the surface. Utilize a product like KILZ Concrete & Masonry Degreaser & Cleaner to cleanse surfaces in good condition that were previously coated. For cleaning and etching any exposed concrete areas, employ KILZ Concrete & Masonry Cleaner & Etcher. Adhere to all directions on the label. Use a product such as KILZ Bonding Primer to spot-prime all uncoated concrete sections, which will enhance the topcoat's adherence to the surface.

- Rustoleum Concrete & Garage Floor Paint + Primer: TDS says - To paint over previously sealed concrete floors, use a palm sander, floor buffer (with sandpaper), or a wire brush to eliminate any loose or flaking old paint, stain, or acrylic concrete sealer. For best results and to ensure adequate adhesion, lightly sand the whole surface and cleanse it using a solvent like acetone. Vacuum, or brush away dust and other debris.

- Fixall Skid-Grip Anti Slip Floor Coating Paint: TDS says - Sealed concrete (curing agents or sealers) should be mechanically abraded or acid etched to create a profile to obtain proper adhesion. Water droplets should immediately penetrate into concrete to determine if coating is possible.

- Mapei Mapecoat Deck T High Build Slip-Resistant Acrylic Deck Coating (For concrete patios, walkways, balconies, and pool decks) Not for garage floors or driveways. TDS says - Concrete should be clean and sound, solid, and free of dirt, residue, oils, grease, curing compounds, laitance, and any contaminant that may interfere with adhesion. The existing concrete should be prepared using engineer-approved methods. Previously painted surfaces should be well adhered. Glossy sealed surfaces need to be abraded to provide adequate keying.

Pro Tip: It's crucial for the sealer being painted over to be well adhered to the concrete because it serves as the foundation for the new concrete paint.

If the existing sealer is not firmly bonded to the concrete, it can compromise the adhesion of the new paint, resulting in the paint peeling or flaking off prematurely.

This can lead to more frequent maintenance or repainting.

do you need to prime concrete before painting

Priming concrete before applying paint is generally recommended, as it provides several benefits that can improve the durability and appearance of the paint:

Improved adhesion:

- A concrete primer creates a uniform, slightly porous surface that allows the paint to adhere better, reducing the risk of peeling or flaking.

even appearance:

- Priming can help to even out the color and texture of the concrete surface, resulting in a more consistent and professional-looking paint job.

REDUCED PAINT ABSORPTION:

- Concrete is naturally porous and can absorb the paint, which may cause the paint to look patchy or uneven. A primer seals the concrete, reducing paint absorption and ensuring a smoother, more uniform finish.

ENHANCED DURABILITY:

- Priming can improve the paint's overall durability, helping it withstand wear and tear, moisture, and other environmental factors.

However, not all concrete painting projects may require priming, depending on the specific paint and surface conditions.

Some paints are formulated as self-priming, and in such cases, a separate primer may not be necessary.

Always consult the paint manufacturer's guidelines and technical data sheets to determine whether priming is needed for your particular project.

how to paint sealed concrete surfaces (step by step)

To paint sealed concrete, follow this step-by-step process:

- Inspect the sealer: Ensure the sealer is well adhered to the concrete. If it's loose or flaking, remove any excess sealant to prevent any problem areas before proceeding.

- Clean the surface: Thoroughly clean the concrete using a product like a concrete degreaser and cleaner. Remove dirt, grease, and any contaminants that could interfere with paint adherence.

- Rinse and dry: Rinse the surface thoroughly with clean water to remove any remaining cleaning solution. Allow the concrete to dry completely (48-72 hours) before moving on to the next step.

- Scuff sanding: Use medium to fine-grit sandpaper on the entire surface to create a slightly rough texture, which will help the paint adhere better. Use a palm sander or floor buffer to speed up this task.

- Remove dust: Sweep or vacuum the surface to remove any dust, debris, or sanding residue.

- Prime the surface (if necessary): If the paint manufacturer recommends a concrete primer, apply primer according to the product's instructions. This step will improve adhesion, even out the surface, and enhance the durability of the paint.

- Paint the concrete: Apply the chosen concrete paint using a brush, roller, or sprayer, following the manufacturer's guidelines. Apply the paint in thin, even coats, allowing each coat to dry before applying the next. Typically, two or more coats are needed over properly prepared concrete for optimal coverage and a durable smooth surface.

- Allow to cure: Let the paint cure according to the manufacturer's recommendations before using the surface. This ensures proper adhesion and allows the paint to reach its maximum hardness.

By following these steps, you can successfully paint over sealed concrete for a fresh, durable, and attractive finish.

Epoxy Concrete Paint you can't use on sealed concrete

When I use a highly durable 2-part epoxy floor paint or a 2-part polyaspartic coating, I always grind off the existing sealer, and I recommend you do too.

Removing the concrete sealer and properly profiling the concrete surface when using a 2-part epoxy paint is essential for adhesion for several reasons:

- Compatibility issues: Not all epoxy floor paints are compatible with existing concrete sealers. Applying epoxy over an incompatible sealer may result in poor adhesion, peeling, or delamination.

- Surface profile: Epoxy primers and floor paints require a slightly rough and porous surface to form a strong mechanical bond with the concrete. A sealed concrete surface is typically smoother and less porous, which can hinder adhesion. Profiling the concrete (e.g., through grinding or acid etching) creates the necessary texture for the epoxy to bond effectively.

- Surface contaminants: Concrete sealers can trap contaminants like dirt, grease, or oils within the surface. Removing the sealer and properly cleaning the concrete ensures a contaminant-free surface, which is essential for optimal epoxy adhesion.

- Consistent appearance: Removing the sealer and profiling the concrete surface allows the epoxy floor paint to bond directly to the concrete. This can result in a more even and consistent appearance, as well as improved durability and performance.

By removing the concrete sealer and adequately profiling the surface, you can ensure the best possible adhesion, durability, and appearance of your epoxy concrete painting project.

2- Part Epoxy Paint products where it's recommended to remove any existing concrete sealers:

- Epoxy-Coat Floor Coating Kit - Best used for garage floors, basement floors, and indoor concrete patios.

- Rust-Oleum RockSolid Garage floor coating kit - Best used on interior garage floors, workshops, basement floors, and family rooms.

- ArmorPoxy Garage Epoxy Floor Kit for Concrete Surfaces - For garages, basements, automotive shops, storage areas, and retail stores

To learn how to properly install a 2-part epoxy paint on interior concrete surfaces, I can teach you in my epoxy floor coating course.

This is a step-by-step video training course where I show you the same steps I take when installing epoxy paint for my customers.

How To test for the type of concrete sealer on your floor

To determine the type of concrete sealer on a concrete surface, you can perform a simple moisture test and a solvent test.

These tests will help you identify if the sealer is a water-based or solvent-based product, as well as its nature (penetrating or topical).

1. Water Droplet Test: Sprinkle a few drops of water on the concrete surface and observe how the water behaves:

- If the water beads up, it indicates the presence of a topical sealer, which forms a protective water-resistant layer on the surface.

- If there's moisture penetration into the concrete without beading, it suggests a penetrating sealer, which works by being absorbed into the concrete pores to provide protection.

2. Solvent Test: Moisten a clean, white cloth with a solvent, such as xylene or acetone. Gently rub the solvent onto a small, inconspicuous area of the concrete surface and observe the results.

- Solvent-based sealers - If the sealer softens, becomes sticky, or shows signs of dissolving, it is likely a solvent-based sealer.

- Water-based sealers - If there is no visible reaction or change to the sealer, it is most likely a water-based sealer.

By performing these tests, you can gain a better understanding of the type of concrete sealer present on the surface.

This information is important when selecting the appropriate products and methods for cleaning, painting, or applying a new sealer.

How To Remove a Concrete Sealer before painting concrete

The best method to remove a concrete sealer depends on the type of sealer (penetrating or topical) and the specific product used.

Here are some common ways to remove concrete sealers:

- Chemical stripper: A chemical stripper is designed to break down the sealer, making it easier to remove. Apply the stripper according to the manufacturer's instructions, usually by brushing or spraying it onto the surface. Allow the stripper to work for the recommended time, then use a scraper, scrub brush, or pressure washer to remove the softened sealer. Take proper safety precautions, such as wearing gloves, goggles, and protective clothing when using chemical strippers.

- Mechanical removal: For thick or stubborn topical sealers, mechanical removal methods such as grinding, sandblasting, or shot blasting can be effective. These methods use specialized equipment to abrade the sealer from the concrete surface. Keep in mind that mechanical removal can be aggressive and may alter the concrete's appearance or texture.

- Solvent washing: For certain solvent-based sealers, a solvent wash can help dissolve and remove the sealer. Moisten a clean, absorbent cloth with a suitable solvent (such as xylene or acetone) and rub it onto the surface in a circular motion. Work in small sections and frequently change the cloth to prevent reapplying the dissolved sealer. Remember to follow safety precautions when using solvents, as they can be hazardous.

- Pressure washing: For mild cases or when dealing with a penetrating sealer, pressure washing can help remove the sealer. Use a pressure washer with a suitable pressure rating and a fan-tip nozzle to avoid damaging the concrete. Pressure washing may not be as effective on thick or stubborn topical sealers.

It's essential to identify the type of sealer present and consider the condition of the concrete before selecting a removal method.

Should I seal the concrete before painting?

Sealing your concrete before painting could be crucial if you think there's any moisture present in or on the concrete. If you have any efflorescence (white powder) on the concrete floor, that's a sign of moisture.

By sealing concrete with a moisture-blocking sealer before painting, you can create a protective barrier that helps prevent paint from peeling or blistering, ensuring a more durable, attractive, and desired finish.

Best Concrete Sealer to use before painting

- LastiSeal Penetrating Brick & Concrete Sealer - Paintable – Suitable as a primer before the use of epoxy, and acrylic concrete paints. It does much more than the common primers by waterproofing the substrate and reducing water vapor transmission, helping to extend the life of paints and clear coatings.

Can I use a Tinted Acrylic Concrete sealer paint on already sealed concrete?

Yes, you can use acrylic (tinted) concrete sealer paint on a concrete floor, patio, walkway, or balcony.

Tinted acrylic concrete sealers differ from regular concrete paints in several ways:

- Composition: Acrylic concrete sealer paints are formulated with acrylic resins, which create a protective film on the surface of the concrete. Regular concrete paints may be based on various resins, such as acrylic, latex, epoxy, or polyurethane, each with its characteristics and performance properties.

- Dual-purpose: Acrylic concrete sealer paints serve a dual purpose: they provide both color and sealing properties. They create a barrier that helps protect the concrete from moisture, chemicals, and UV damage while also enhancing its appearance. Regular concrete paints primarily focus on providing color and may not offer the same level of protection as a sealer.

- Breathability: Acrylic concrete sealer paints are typically breathable, allowing moisture vapor to escape from the concrete surface, reducing the risk of trapped moisture causing paint peeling or blistering. Regular concrete paints, especially non-breathable types like epoxy, may not offer the same level of breathability.

- Ease of application: Acrylic concrete sealer paints are often easier to apply and have a faster drying time compared to other types of concrete paints, such as epoxy or polyurethane. This makes them more user-friendly for DIY projects or quick turnarounds.

- Durability: While acrylic concrete sealer paints offer good protection, they may not be as durable or chemical-resistant as other types of concrete paints like epoxy or polyurethane. However, they are still suitable for various applications, including residential and light commercial use.

How do you prepare sealed concrete for painting?

To prepare sealed concrete for painting, first clean the surface thoroughly with a concrete cleaner and degreaser to remove any dirt, grease, or contaminants.

Next, check for compatibility between the sealer and the paint, and ensure the sealer is well-adhered to the concrete. If needed, remove any loose or peeling sealer, and lightly scuff sand the surface for improved adhesion.

Finally, apply a bonding primer specifically designed for concrete surfaces before painting.

What kind of primer should I use on sealed concrete?

For sealed concrete, use a bonding primer specifically formulated for concrete or masonry surfaces. This type of primer ensures proper adhesion between the sealer and the paint.

Always consult the primer manufacturer's guidelines for compatibility with your specific sealer and paint.

Do I need to acid-wash sealed concrete before painting?

Acid-washing sealed concrete before painting a concrete floor may be necessary to remove the sealer and create a rough, porous surface for proper paint adhesion.

If you do an acid wash with muriatic acid, keep in mind this product is harmful to touch and breathe so take the proper safety precautions and remember to apply a baking soda rinse after you acid wash to neutralize the acid.

Consult the paint manufacturer's directions to determine the recommended surface preparation steps for your specific product.

In Conclusion: Can you paint over concrete sealer

If you want to paint concrete over concrete sealer, it is possible, but it requires careful consideration of the sealer type, paint compatibility, and proper surface preparation.

Ensuring the sealer is well-adhered, compatible with the chosen paint, and the surface is suitably prepared will result in a successful, durable, and attractive finish.

In some cases, it may be necessary to remove the sealer and profile the concrete floor to achieve the best possible adhesion and performance. Always consult the manufacturer's guidelines for both the sealer and paint to ensure a successful application and long-lasting results.

Here are some other frequently asked questions:

- Can I apply epoxy paint over a concrete sealer? Epoxy paint may not adhere well to certain concrete sealers. Check the compatibility of the epoxy paint with the existing sealer, and if necessary, remove the sealer and profile the concrete surface before applying epoxy paint.

- How long should I wait before applying paint over a freshly sealed concrete surface? Wait for the sealer to fully cure before applying paint, which typically takes 24-72 hours. However, always follow the sealer manufacturer's recommendations for the specific curing time.

- Can I use water-based paint over a solvent-based concrete sealer (or vice versa)? Using water-based paint over a solvent-based sealer (or vice versa) may result in compatibility issues and poor adhesion. Consult the paint and sealer manufacturers' guidelines to ensure compatibility before application.

- How do I know if my concrete sealer is still effective or needs to be reapplied before painting? Perform a water droplet test: sprinkle a few drops of water on the surface. If the water is absorbed, the sealer may no longer be effective, and reapplication may be necessary. If the water beads up, the sealer is still active.

- Can I use a clear sealer over painted concrete? Yes, you can use a clear sealer over painted concrete to provide additional protection and enhance durability. Ensure compatibility between the paint and the sealer and follow the manufacturer's guidelines for application.

Most popular pages: